used cars bountiful

2. Corrosion Resistance Many metal flashing products are treated with protective coatings or are made from materials like aluminum or stainless steel, which are naturally resistant to rust and corrosion. This property ensures that the flashing maintains its performance and appearance over time, which is crucial for maintaining roof integrity.

flashing roof metal sheet manufacturer

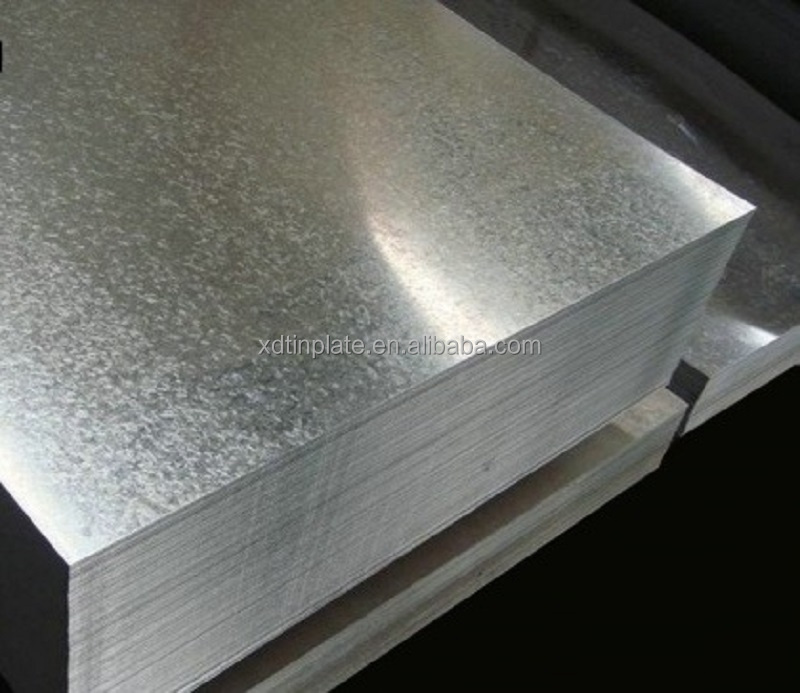

Once the wire is drawn, it undergoes cleaning to remove any impurities or oxidation that may have occurred during the drawing process. After cleaning, the wire is then subjected to the galvanization process, where it is coated with zinc. Factories ensure that the coating adheres properly, providing excellent corrosion resistance.

galvanized iron wire bwg 21 factories

Moreover, these factories have increasingly incorporated sustainability into their operations. With rising environmental consciousness, many manufacturers are opting for recycled materials or developing processes that minimize waste. Some facilities have implemented closed-loop systems, wherein scrap materials generated during production are recycled back into the manufacturing process. This commitment to sustainability not only reduces the carbon footprint but also attracts eco-conscious consumers who are more likely to support brands that prioritize environmental responsibility.

tin trash can factories